Loading... Please wait...

Loading... Please wait...- Home

- Equipment

- Digital Cutters

- Flatbed Cutters & Routers

- APEX PRO 2516 Digital Flatbed Cutter 63” x 98” Cutting Area, 450w (APEX-PRO-2516)

Categories

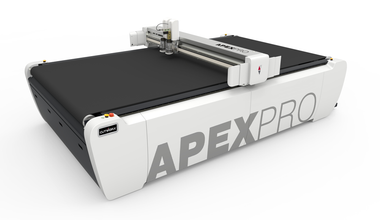

APEX PRO 2516 Digital Flatbed Cutter 63” x 98” Cutting Area, 450w (APEX-PRO-2516)

Product Description

APEX PRO 2516 Digital Flatbed Cutter 63” x 98” Cutting Area, 450w (APEX-PRO-2516)

Features & Benefits:

The Apex Pro series of digital flatbed cutters are designed for a variety of finishing requirements for Graphics, Packaging, Textile, & Upholstery Markets and more. Increase your productivity and profitability by having an in house multi-functional precision high speed digital cutting solution that can cut, crease, decal cut and oscillate cut materials. The Apex series is designed with over 27 years of experience engineering cutting tables.

-

Multiple Table Size Solutions to match application

-

Dual interchangeable cutting head positions available for many tool combinations

-

Tool Head Modules controlled independently

-

Optical Auto Tool height calibration

-

German engineered 450w router

-

Various material unwinding devices

-

Variable Vacuum Zone table controlled by the interface to adjust the vacuum power & positions for different material needs

-

Aerospace aluminum table for precision and accuracy

-

Service, Support, Parts & Supplies provided by and in stock at our APC Chambersburg, PA showroom.

-

Precision Cutting: Apex cutters provide extraordinary precision, ensuring exact cuts every time, saving on material wastage and reducing errors.

-

Versatility: Apex cutters can handle a wide range of materials, from paper and cardstock to leather and certain types of plastic, making them suitable for various applications.

-

Increased Productivity: With automated features for cutting, these cutters significantly increase productivity and efficiency by reducing manual labor.

-

Multi-Tool Capacity: The ability to manage multiple tool positions on a single sheet allows for an adaptable cutting process, catering to a variety of production needs.

-

User-Friendly: With an intuitive control system, these cutters are easy to operate, even for beginners, reducing the learning curve.

-

Durability: Apex cutters are designed to withstand high-volume operations, ensuring reliable, long-term performance.

-

Safety Measures: With safety features built into the design, these cutters prioritize operator safety during operation.

-

High-Speed Operation: Apex cutters operate at high speeds without compromising on accuracy, reducing production time.

-

Seamless Integration: Apex cutters can be easily integrated into existing production lines, making them a valuable addition to any operation.

-

Cost-Effective: By combining multiple functions into one machine and reducing manual labor, these cutters are a cost-effective solution for businesses of all sizes.

Router and Tool Options

-

450w Air Cooled Spindle/Router (60k rpm)

-

Creasing Tool (CT)

-

Driven Rotary Tool (DRT)

-

Electronic Oscillating Tool (EOT)

-

Electronic Oscillating Tool 4 (EOT-4)

-

Kiss Cut Tool (KCT)

-

Perforating Tool (PT)

-

Pneumatic Oscillating Tool (POT)

-

Pneumatic Rotary Tool (PRT)

-

Universal Cutting Tool (UCT)

-

Variable V-Cut Tool (V-VCT)

-

V-Cut Tool (VCT)

Applications:

-

Acoustic Panel products

-

Acrylics, Plexi, Lexan

-

Aluminum & Aluminum Composites

-

Banner stock

-

Corrugated boards (paper and plastic)

-

Packaging Prototyping

-

POP Displays

-

Foam boards, foam, Gator foam, Poster board

-

Gasket Cutting

-

Honeycomb – Recycled board

-

KT Board

-

Labels

-

MDF

-

Papers and card stocks

-

PSA Vinyl

-

PVC/Sintra, PET, Styrene

-

Reflective Vinyl

-

Sticker and Decal Production

-

Textiles and Fabric Cutting

Specifications:

Effective Cutting Area (mm): 2500 x 1600

Machine Dimension (mm): 3200 x 2400

Weight: 1322.77lbs – 1984.16lbs

Max Cutting Speed: 1800mm/s

Max Cutting Thickness: 50mm/1.97in

Cutting Precision: 0.1mm/.004in

File Format: DXF, HPGL, ISO

Material Hold Down: Vacuum

Pump Power: 7.5KW/9KW

Electric Power: 220V/60HZ, 380V/60HZ

Operation Environment: Temperature: 32°F – 104°F, Humidity: 20% – 80%RH