Loading... Please wait...

Loading... Please wait...Categories

Made in America! Getting started in Printed Sports Apparel - Part 2

Posted by Dave Mee on Jun 13th 2016

This is the second part in our series detailing getting started in producing your own sublimated sports apparel, right here in the US! Avoiding the long lead times and lack of control that goes with outsourcing your production can be easier than you think. This post details the the different types of heat presses available. If you've not yet read Part 1, I suggest you start there and then come back to this post.

http://store.apcink.com/blog/made-in-america-getting-started-in-printed-sports-apparel-part-1/

SUBLIMATION TRANSFER PAPER:

While there is such a thing a "Direct-to-Fabric" Sublimation, we have seldom seen it used for the apparel industry. Fabric that is directly printed requires a special coating to help hold the ink dots in place prior to heat pressing and prints made directly on fabric are typically less sharp than those made by transfer. Additionally, the stretch fabrics popular in sports can be very difficult to transport through a printer and require expensive belt-transport systems.

For apparel production you need a paper to put your ink on before pressing to the fabric. While there are a multitude of papers available, here's what we recommend:

Beaver TexPrint HR 105gsm

44” wide x 274 ft length - MSRP = $109.34

54” wide x 393 ft length - MSRP = $177.98

64” wide x 393 ft length - MSRP = $209.78

Beaver TexPrint HR is a very popular sublimation transfer paper. This paper is intended for rotary Calendar presses. The “HR” stands for “High-Release” meaning that a high amount of ink is released from the paper when put through the Heat Press. This paper is 105 gsm weight so is very resistant to deforming when the wet ink lands on it. Costs on this paper is about $0.10 per square foot based on buying single rolls. Significant discounts apply for purchasing whole pallets (36 rolls).

Beaver TexPrint Supreme - Tack 92gsm

44” wide x 328 ft length - MSRP = $104.88

54” wide x 492 ft length - MSRP = $172.67

64” wide x 393 ft length - MSRP = $209.78

Tacky papers are designed for use with Flatbed type heat presses. The paper incorporates a thermal adhesive that sticks the fabric to the paper. This prevents the paper from lifting up or moving when the press is opened, thus avoiding an undesirable blurring or doubling of the images known as “ghosting”. Typically tacky papers typically cost a little more, but for some strange reason this new paper from Beaver actually costs less that the standard types. We’ve been greatly impressed with this paper and have even had success running it through rotary calendars where ghosting was an issue. Cost on this paper is about $0.076 to $0.0872 per Square foot (the narrower, shorter rolls costing more). Again, discounts apply for purchasing whole pallets (36 rolls).

All Beaver Papers are made in Georgia, USA.

SUBLIMATION PRESSES:

How Sublimation Heat Presses work:

Typical settings when performing sublimation for textile are approximately 400 deg F, with a dwell time of about 40-45 seconds and most polyesters handle this high heat without problems. Some specialized materials can yellow, loose their elasticity or melt at 400 deg, so in these cases the temperature can be lowered and the dwell time increased, however it should be noted that sublimation doesn’t occur properly as temps drop below 320 deg F. During sublimation the paper must be held tightly under pressure against the fabric to ensure sharp transfers.

SUBLIMATION HEAT PRESSES - FLATBED TYPE:

Flatbed Heat presses typically offer a lower price of entry (although very large flatbed presses can exceed the costs of similarly wide rotary calendars). They offer versatility in that items such as pre-stitched garments, mouse-pads, carpet mats and even hard substrates such as name-plates, ceramic tiles and the like can be sublimated in additional to just unfinished fabric. The disadvantages are that you’re limited to the size of the bed so you cannot produce roll-goods. The labor requirements can be high as an operator is required to be in attendance for the entire time that work is being produced, also through-put is often lower as the operator must wait for the pressing cycle to end (typically 40-45 seconds) before the articles can be removed and another set of fabric and prints loaded, however dual-pallet and shuttle-type presses overcome this limitation.

Below are a few different flatbed models worth considering:

HIX SwingMan 25

20" x 25” MSRP = $3,220

http://hixgraphics.com/swingman-25p

This is your basic “T-Shirt” type press. Top element swings clear of the bottom platen for loading paper and fabric.Press is closed by pulling down on a handle that applies pressure. Too small for real production but a good choice for testing or sampling.

Geo Knight MAXI-PRESS

32” x 42”MSRP = $8,950

https://www.heatpress.com/product.php?pn=25

Large manually operated Draw-Slide Press. Tray slides in and large handle pulled down to close the press. This is a popular choice for those who need a large press on a budget, but as it has only a single tray you must wait 40-45 seconds for each job you press.

Practix Mfg OK-160 Draw Slide Press

32” x 42” MSRP = $13,900 (reciprocating trays add $4,000)

40” x 48” MSRP = $15,500 (reciprocating trays add $5,000)

42" x 66” MSRP = $19,500 (reciprocating trays add $5,500)

http://practix-usa.com/dye-sublimation-equipment/flatbed/drawer-slide/ok-160/

These presses are very easy to use as the tray slides out, clear of the heating element allowing for easy loading/unloading of fabric. Platen is closed and pressure is applied by compressed air for reduced operator fatigue. By adding the reciprocating-tray option, one job can be sublimating while another is being loaded/unloaded, allowing for uninterrupted operation.This configuration is greatly preferred over the “Clamshell” and “Swing” types for production work.

Practix Flatbed Presses are made in Georgia, USA. We are an authorized agent for Practix so please contact us for more information.

SUBLIMATION HEAT PRESSES - ROLL CALENDAR TYPE

Looking like something you might expect to see in an industrial laundry, Roll-type Calendars are large, made from a lot of heavy-duty metal and usually more expensive than Flatbeds. They are however generally faster than flatbed presses, require less operator attendance and are the only option if you intend to produce rolled goods.

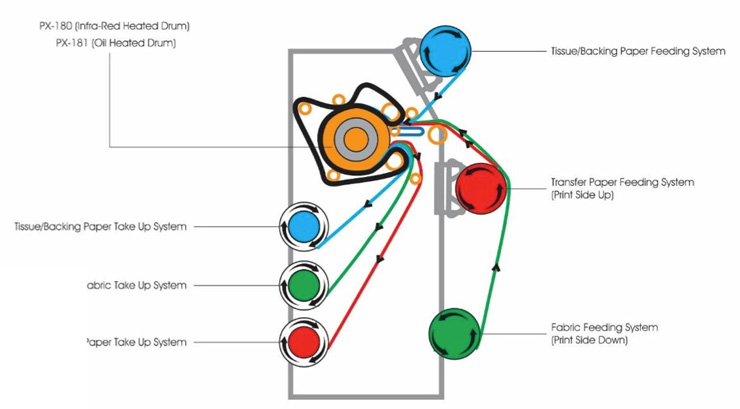

Paper and fabric are fed together (often on a roll) into the unit and a heat resistant belt holds the fabric tightly against the rotating drum. The fabric and paper exit out the other side of the drum where they separate and are wound up on their own individual take-up spools - See diagram below:

You’ll also notice that there is a third roll in this diagram (shown in green). When sublimating to thin or mesh fabrics a roll of protection-tissue or backing-paper must be run also to prevent ink sublimating right through the fabric and staining the belt. This is also necessary when doing “cut-piece” production, where the design on the paper bleeds out larger than the cut fabric piece. More on this later.

The rotation speed of the drum determines determines the dwell time. Calendars with larger drum diameters mean that you can move the fabric faster while still achieving 45 seconds of contact. Drums in the 7” - 14” diameter range are sufficient for small to medium scale production.

There are two types of heating technology, known as “electric” and “oil”. The descriptions are somewhat confusing as both types use electricity to heat the drums. The “Oil” type uses a drum that is filled with oil that is heated to high temperatures by heating elements. The use of oil means that temperature fluctuations are very small and heat is very even across the width of the drum. This translates to very consistent color when stitching together garment pieces that may have traveled under different parts of the drum. The “Electric” type is cheaper and traditionally used heater coils to heat the air inside the drum. “Electric” drums are not as well regarded as they typically have less even heat, particularly at the edges and are more prone to heat fluctuations and in turn, color fluctuations however the newer “Infra-red” technology looks promising at solving these issues while keeping the price low.

GTC 81/1850 SP Flowline

65” x infinite length.

7.7” Drum - Oil Heat

Roll + piece production

Price = $45,000 approx

Power: 220 Volt 3-Phase.

Watch the video: http://www.youtube.com/watch?v=R7VnczA-Qao

Based in the Netherlands, Klieverik makes very nice machines. They also produce very nice product videos too, and this video above does a great job of showing how piece-production is done for sports-apparel. One of the nice things about doing cut-piece production, is that you can switch between fabric types on the fly, say a wicking material for the fronts, mesh for the back and something else again for the sleeves. Another interesting thing to note is that they are using tacky paper in this video - see how they have to peel the print from the paper when it comes out the back end? If using regular sublimation paper the prints would fall off into a basket or box. Tacky paper is probably not necessary on a calendar of this calibre, but it can help if extra sharpness is needed.

Klieverik Calendar pricing is “all-in” meaning that all freight, duties and installation is included. We are an agent for Kleverick in the USA.

Royal Sovereign PX-180 Infrared Heat 65” Sublimation Calendar

http://store.apcink.com/royal-sovereign-inpress-px-180-calendar-infra-red-heat-transfer-press-65/

65” x infinite length.

10” Drum - Infrared Heat (PX-181 oil heat available for additional $12,000)

Roll and piece production.

MSRP = $26,500 (work-table for piece production - add $3,500)

Power: 220 Volt Single Phase

Royal Sovereign is primarily known for their excellent laminators but recently got into the Calendar game. The PX-180 does not have an oil filled drum, but instead uses infra-red heaters inside the drum. It is versatile in that it can be used for both roll-to-roll and piece-production (see video above). While these machines are relatively new to the market, we have done extensive testing and have several units out in the field. The heat on these infra-red machines does indeed seem very consistent and the build quality and ease-of-use is excellent. This is certainly a lot of calendar for the money and we have no hesitation recommending them even for high-volume shops.

Requires only 220 volt Single-Phase. Distributed and serviced out of NJ. We are a reseller of Royal Sovereign so please contact us with any questions.

Practix Mfg OK-10 Rotary Heat Transfer Machine

66” x infinite length.

10” Drum - Oil Heat

Roll Production = $34,950

w/ Piece Production options = $43,650

http://practix-usa.com/dye-sublimation-equipment/rotary-drum/roll-to-roll-application/ok-10/

As with the flatbed options, Practix Roll-Calendars are made in Georgia, USA and are very well regarded. Uses an oil-filled drum for even and consistent heat. Can be purchased as a straight roll-to-roll Calendar or you can add a 70” table, and additional feed/takeup for protection tissue to use this for piece-production.

Requires 220 Volt 3-Phase.

While there are machines available with very large drums and very high speeds, I have not included these here as they are outside the "getting started" theme of this post. Certainly if you are looking for information on high volume equipment please contact us and we will be happy to give our recommendations.

Hopefully this gives an overview of the different types of budget-conscious calendars available. Any questions, feel free to email us at info@apcink.com or call 855-927-2465.

Thanks for reading!

- DM